How to Maintain Your Industrial Scales for Long-Term Accuracy and Durability

How to Maintain Your Industrial Scales for Long-Term Accuracy and Durability

Blog Article

How Industrial Scales Work: A Detailed Introduction for New Users

Recognizing the technicians behind industrial scales is important for new individuals who want to make certain precision in their measurements. As we explore these parts, one need to think about exactly how these elements connect to improve performance in varied industrial applications.

Basics of Industrial Scales

Industrial ranges are crucial devices used across different industries, including production, logistics, and agriculture, to ensure accurate weight measurements of hefty lots. The fundamental concept behind commercial ranges includes the conversion of weight into a measurable form that can be displayed digitally or analogically. These ranges use different devices, such as lots cells or mechanical bars, to establish the weight of things put upon them.

Along with their measurement capabilities, industrial scales are created to withstand severe atmospheres, including robust building that resists dirt, moisture, and hefty impacts. Calibration and upkeep are important to guarantee precision, as also small inconsistencies can result in significant economic ramifications. By comprehending the basics of commercial scales, users can value their value in different industrial applications.

Kinds Of Industrial Scales

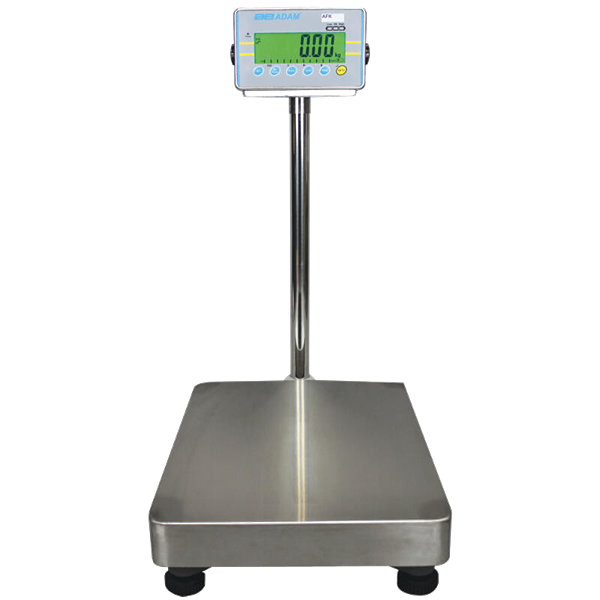

Different sorts of commercial scales accommodate the varied needs of different sectors, each created to deal with specific weighing jobs with accuracy and dependability. Among one of the most usual types are floor scales, which are suitable for evaluating cumbersome and heavy items. These scales usually feature large platforms and can suit palletized items, making them necessary in storehouses and shipping facilities.

An additional type is bench scales, which are typically made use of for smaller things in manufacturing and retail settings. They provide exact measurements for items that need accuracy, such as chemicals or parts in setting up lines (Industrial Scales). For mobile procedures, portable scales supply versatility and convenience of transport, appropriate for fieldwork or temporary setups

In applications calling for high-capacity measurements, such as in mass product handling, crane scales and load cells are utilized. These ranges can measure loads suspended from a crane or other training device, guaranteeing safety and security and accuracy during operations. In addition, specialized ranges like checkweighers are used in manufacturing lines to keep quality assurance by making certain that products fulfill weight specifications. Each type of industrial scale plays a critical role in improving operational performance and precision throughout numerous fields.

Just How Considering Devices Job

Evaluating systems are crucial parts that make it possible for exact dimension of mass across different industrial ranges. These systems use numerous concepts of physics and engineering to provide specific weight analyses, important for inventory monitoring, quality assurance, and compliance with governing requirements.

One common sort of evaluating mechanism is the lots cell, which operates on the concept of stress evaluates. When a lots is applied, the lots cell deforms a little, creating an electric signal proportional to the weight. This signal is then converted into a legible weight dimension by the range's electronic devices.

One more widely used system is the mechanical balance, which uses a system of weights and levers. Industrial Scales. This method relies upon the concept of equilibrium, where the weight of the item being measured is balanced versus known weights, permitting for direct measurement

In addition, pneumatic and hydraulic scales take advantage of liquid dynamics principles to gauge weight. These systems use the stress applied by a load to figure out weight, offering high accuracy for substantial loads.

Appropriate Use Techniques

When using commercial ranges, adhering to appropriate use strategies is important for keeping and guaranteeing precise dimensions tools integrity. It is vital to pick the ideal range for your specific application, as scales vary in capability and accuracy.

Prior to weighing, ensure that the scale is put on a this article secure, degree surface area without disturbances or resonances. This will certainly help to decrease mistakes brought on by outside aspects. Additionally, calibrate the range according to the manufacturer's specs before make use of, making certain that it is functioning properly.

When placing things on the scale, distribute the weight equally to avoid tipping or damaging the tools. Always enable the scale to stabilize before tape-recording the weight, as variations might occur during preliminary positioning. For bulk materials, make use of containers that are proper for the range dimension to stop overloading.

In addition, stay clear of placing extremely warm or cool things straight on the range, as temperature level variants can affect accuracy. Finally, keep the evaluating system tidy and cost-free of particles to prevent contamination and make sure trustworthy outcomes. By following these techniques, users can make best use of the efficiency and long life of their commercial ranges.

Upkeep and Calibration Tips

Ensuring the long life and precision of industrial scales requires thorough upkeep and routine calibration. A preventive upkeep timetable is crucial; it should consist of regular evaluations to recognize wear and tear, especially on lots cells and other delicate components. On a regular basis cleaning the scale's surface area and ensuring the surrounding area is devoid of debris will certainly assist keep its integrity and performance.

Calibration is equally essential and ought to be performed at routine periods or whenever the range experiences considerable modifications in temperature, humidity, pop over to these guys or physical variation. Use qualified calibration weights that are traceable to national requirements for precision. Paper each calibration session carefully to track performance in time and determine any kind of trends or reoccuring concerns.

In addition, bear in mind the scale's setting. Avoid putting it near resources of resonance, electromagnetic interference, or extreme temperatures, as these factors can adversely affect measurements. Finally, train all operators on correct range use and upkeep procedures to make sure constant performance and accuracy. By adhering to these upkeep and calibration pointers, customers can boost the dependability of their industrial scales, guaranteeing optimal operation in any setting.

Verdict

Recognizing the mechanics behind industrial scales is essential for new individuals who want to guarantee accuracy in their measurements.Industrial scales are necessary devices made use of throughout numerous fields, consisting of production, logistics, and agriculture, to ensure accurate weight measurements of heavy tons. The essential principle behind industrial scales involves the conversion of weight into a measurable kind that can be displayed digitally or he has a good point analogically. By recognizing the fundamentals of industrial scales, individuals can appreciate their value in different industrial applications.

In final thought, comprehending the operation and maintenance of industrial scales is essential for ensuring exact weight dimensions in various applications. (Industrial Scales)

Report this page